- Home

- Quality

Quality

Quality Assurance

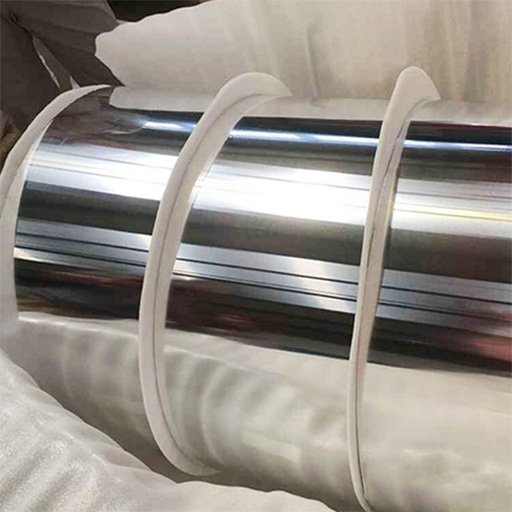

Ultima Aluminium is steadfastly enhancing its production capabilities. The company continuously invests in advanced technologies, modern machinery, and state-of-the-art equipment. These investments are pivotal in maintaining high standards of product quality. The focus on upgrading their facilities underscores a commitment to excellence. By adopting new technologies, Ultimamesa ensures efficiency and precision in its processes.

The integration of cutting-edge machinery helps in achieving superior product quality. Regular upgrades to equipment prevent downtime and enhance productivity. Ultimamesa strategy revolves around continuous improvement. This approach is fundamental to their quality assurance measures. Investing in innovation is seen as a pathway to maintaining market competitiveness.

Quality at Every Step

Bursting Strength Tester

One of the standout features of this device is its ability to function without any manual interference. The pneumatic application is engineered to deliver precise pressure, which is crucial for obtaining accurate test results. The hydraulic pressure system works in harmony with the pneumatic controls, ensuring that the load is applied evenly and vertically.

Pinhole tester

The Pinhole Tester for Aluminum Foil, commonly referred to as the Light Box, is a specialized piece of equipment designed to detect pinholes in aluminum foils. These pinholes are essentially micro leaks on the foil surface that can compromise the integrity of the packaging. Detecting these imperfections is crucial, especially for aluminum foils used in food and pharmaceutical packaging.

The presence of pinholes in aluminum foil can significantly reduce the shelf life and stability of the products they are meant to protect. This is because pinholes allow air, moisture, and other contaminants to penetrate the packaging, leading to spoilage or degradation of the contents.

Microbial Testing of Aluminium Foil

Ultimate Tensile Strength Test

The breaking strength (easiness of tearing) of aluminum foil for food is measured. Both ends of the aluminum foil are gripped and pulled until it breaks, then the peak force represents the breaking strength. To grip the thin and fragile aluminum foil firmly without tear, a flat chuck with parallel claws (optional) is used . In addition, the optional graphing software shows the entire force transition until the aluminum foil breaks, which helps you analyze the breaking strength.